Mineral Products

Mineral

products

Eagle Petrochem produce ron Ore) powde r.

During the past years we have succeeded to receive different certificates

from Oil companies.

Drilling Mud

Drilling mud, also called drilling fluid, in petroleum engineering, a heavy, viscous fluid mixture that is used in oil and gas drilling operations to carry rock cuttings to the surface and also to lubricate and cool the drill bit. The drilling mud, by hydrostatic pressure, also helps prevent the collapse of unstable strata into theborehole

Drilling muds are traditionally based on water, either fresh water, seawater, naturally occurring brines, or prepared brines. Manymuds Synthetic

A typical water-based drilling mud contains a clay, usuallybentonite barite borehole

Drilling Machinery

Drilling fluids are also employed in the drilling of water wells.

Drilling Mud

Drilling mud, also called drilling fluid, in petroleum engineering, a heavy, viscous fluid mixture that is used in oil and gas drilling operations to carry rock cuttings to the surface and also to lubricate and cool the drill bit. The drilling mud, by hydrostatic pressure, also helps prevent the collapse of unstable strata into the

Drilling muds are traditionally based on water, either fresh water, seawater, naturally occurring brines, or prepared brines. Many

A typical water-based drilling mud contains a clay, usually

Drilling Machinery

Drilling

mud is pumped down the hollow drill pipe to the drill bit, where it

exits the pipe and then is flushed back up the borehole screens mud borehole

Drilling fluids are also employed in the drilling of water wells.

General Description:

Uses: Foundries, Well

drillers, Iron ore manufacturers the main consumers of Bentonite.

Foundries use Bentonite

when pouring metal cast molds. The clay withstands higher temperatures and the

excessive heat will not cause the clay to lose its chemical structure.

Well drillers use Bentonite

when drilling oil or gas wells. Bentonite it

I ron crushed taconite mills

·

Clarifying agent for wine, vinegar,

fruit juice, beer, oils

·

Sealant in sanitary landfills and

lagoons

·

Water purification systems

·

Binder in fertilizers and animal feed

products

·

Carrier for insecticides

Packing:

·

2200 lb

High-grade barium sulphate

RECOMMENDED USE

Primarily for mud rotary drilling, barite

ADVANTAGES

High specific gravity; raises drilling fluid density with

minimum

PROPERTIES

Specific Gravity: 4.2 (minimum), Moisture Content: Less than

1%, Bulk Density: 150 lbs/ft3, Mineral Content: 94% barium sulphate

PACKAGING

· 1500 kgs Jumbo bags

·

50 lbs paper bags

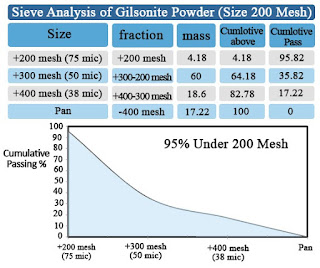

OUR GILSONITE

In respect of our company's long-term experience regarding extracting,

exploiting and producing of Natural Bitumen it is notified that this company is

the only and the first powder bitumen producers sizing under 200 mesh and the

unique operating of gilsonite

· Oil base drilling

· Printing Ink

· Roofing Felt

· Paint and Coat

· Mix with Asphalt

· Construction

· Cementing

· Foundry

· Foundry Sand Additive

· Steel Creating Additives

Mode of order:

·

In to Bulk

·

In to powder under 200 mesh

·

Sizing in accordance with Client

request

· jumbo

· 25 kg laminating bags

· corresponding palletised shrink

stretch it’s

The quality of The Goods:

Analysis in accordance with

Standards ASTM D482, ASTM D2042, ASTM D3142, ASTM D3174

Sampling and analysing

There are many

national and international specifications and tests stipulated by various

authorities, contracts and building regulations around the world. we

Analysis of commercial bulk Gilsonite to ASTM, ISO, EN, and similar

specifications

Analysis of the basic Gilsonite performance such

·

Solubility in CS2

·

Solubility in trichloroethylene

·

Softening Point Cº

·

Ash content %

Density

Density

Storage monitoring to assess oxidation state

Testing of packing Gilsonite over time to asses batch lifetime

QUALITY PROGRAM

All testing laboratories participate in

an international proficiency test scheme for Gilsonite. These round robin tests

act as a performance indicator and help to maintain a consistently high level

of quality and assurance from our labs.

Eagle petrochem

Gilsonite

Oil based drilling fluids and advances in drilling fluid compositionsare

described organoclays where in

By way of background and in the particular case of oil muds or oil-based drilling fluids, organophilic clays have been used for the past 50 years as a component of the drilling fluid to assist in creating drilling fluids having properties that enhance the drilling process. In particular, oil-based drilling fluids are used for cooling and lubrication, removal of cuttings and maintaining the well under pressure to control ingress of liquid and gas.

Gilsonite

Gilsonite

The invention relates to a composition comprising an HPHT fluid loss control aid, stable at elevated temperatures and which also acts as an excellentshale asphaltite asfaltit , uintaite

The HPHT fluid loss controlaid solubilized causticized

To achieve these and other advantages, and in accordance with the purpose of the invention, as embodied and broadly described, the invention comprises a composition comprising an HPHT fluid loss control aid stable at elevated temperatures, and which also acts as an excellentshale

The HPHT fluid loss control aid broadly comprises Gilsonite, anasphaltic

Combination loss

has

The invention also comprises a product made by combining the components of the composition as well as a product made by the process of adding the composition or product to a drilling fluid. Lastly, the invention comprises a process for controlling HPHT fluid loss in subterranean wells by adding the composition or product into a subterranean well.

Drilling fluids as used in the written description and the claims, include not only conventional drilling fluids or drilling muds including petroleum oil, synthetic oil and fresh water and salt water types as known in the art but also completion fluids and work over fluids.

Gilsonite

It is a natural occurring Gilsonite used for HTHP filtration control in invert oil/synthetic base systems at temperatures above 400 F (205 C).

It is compatible with all invert oil / synthetic base systems and can be used both in the initial formulation or for treatment while drilling.

Initial treatment in the range of 2–10lb bbl

Pilot testing should be conducted to determine actual concentration needed in each case. If CONFI-TROL HT is to be added to a newly mixed mud prior to displacement, the addition should be made after all other components have been mixed thoroughly.

Gilsonite

Gilsonite Asphasol sulfonated Gilsonite Asphasol

Typical Physical Properties of Asphasol

Physical appearance: Black, free-flowing powder

Ph

Solubility in water: Minimum 50% by weight

Applications of Asphasol

Gilsonite Asphasol Gilsonite Asphasol

Normal concentrations of Gilsonite Asphasol shale inhibitor range from 2 to 10lb bbl

(5.7 to 28.5 kg/m3) for most applications.

Advantages of Gilsonite Asphasol

Asphasol

Contains no surfactants

Premixing

Inhibits swelling and water-wetting ofshales

Reduces High-Temperature, High-Pressure (HTHP) fluid loss

Reduces torque and drag

Improves wall cake quality

Asphasol

Gilsonite asphaltite lb muds

The low specific gravity of Gilsonite powder helps improve its ability to control lost circulation. However, this feature can also cause the additive to separate to the top of thin slurries and slurries containingdispersants bentonite

Gilsonite

The environmental granular asphalt which sizes are of 0.1/40MM This recycled granular asphalt is mostly used for new roads layers and finished lines our products are backed by the European union certificates with an SGS report on each shipment.

Asphalt granular Primary use:

This type of granulate is used for stabilizing roads (second layers) and also for the first layer, mixed with cement (2%). Bitumen emulsion (2%) or any other binding.

As a result, the roads can be constructed at less cost and these roads are less harmful to the environment and much more durable.

Product details asphalt granular

We sell asphalt granular 0.1/40 also known as bitumen asphalt. Our productshas oeso eural .

Chemical composition (pak ) benzo A) pyreen evoa

Gilsonite

Gilsonite

It also soluble without heating in Aliphatic and low aromatic solvents (VM&P and other Naphtha,Ink Oils Gilsonite

Gilsonite

Water-based Gilsonite is natural bitumen environmentally safe and specially formulated to protect hole shale water base drilling.

The drilling fluid serves a number of functions including taking heat away from the drill bit and facilitating the return of drill cuttings to the surface. There are three main types of drilling mud, including Gilsonite muds.

The present invention deals with the consequences of using water-based drilling Gilsonite muds. When the hydrostatic pressure of the drilling mud in thewellbore wellbore

In many applications, the drilling Gilsonite mud is intended to be deposited in and/or on thewellbore wellbore wellbore

Oil based drilling fluids and advances in drilling fluid compositions

By way of background and in the particular case of oil muds or oil-based drilling fluids, organophilic clays have been used for the past 50 years as a component of the drilling fluid to assist in creating drilling fluids having properties that enhance the drilling process. In particular, oil-based drilling fluids are used for cooling and lubrication, removal of cuttings and maintaining the well under pressure to control ingress of liquid and gas.

The invention relates to a composition comprising an HPHT fluid loss control aid, stable at elevated temperatures and which also acts as an excellent

The HPHT fluid loss control

To achieve these and other advantages, and in accordance with the purpose of the invention, as embodied and broadly described, the invention comprises a composition comprising an HPHT fluid loss control aid stable at elevated temperatures, and which also acts as an excellent

The HPHT fluid loss control aid broadly comprises Gilsonite, an

The invention also comprises a product made by combining the components of the composition as well as a product made by the process of adding the composition or product to a drilling fluid. Lastly, the invention comprises a process for controlling HPHT fluid loss in subterranean wells by adding the composition or product into a subterranean well.

Drilling fluids as used in the written description and the claims, include not only conventional drilling fluids or drilling muds including petroleum oil, synthetic oil and fresh water and salt water types as known in the art but also completion fluids and work over fluids.

It is a natural occurring Gilsonite used for HTHP filtration control in invert oil/synthetic base systems at temperatures above 400 F (205 C).

It is compatible with all invert oil / synthetic base systems and can be used both in the initial formulation or for treatment while drilling.

Initial treatment in the range of 2–10

Pilot testing should be conducted to determine actual concentration needed in each case. If CONFI-TROL HT is to be added to a newly mixed mud prior to displacement, the addition should be made after all other components have been mixed thoroughly.

Typical Physical Properties of Asphasol

Physical appearance: Black, free-flowing powder

Solubility in water: Minimum 50% by weight

Applications of Asphasol

Normal concentrations of Gilsonite Asphasol shale inhibitor range from 2 to 10

(5.7 to 28.5 kg/m3) for most applications.

Advantages of Gilsonite Asphasol

Contains no surfactants

Inhibits swelling and water-wetting of

Reduces High-Temperature, High-Pressure (HTHP) fluid loss

Reduces torque and drag

Improves wall cake quality

The low specific gravity of Gilsonite powder helps improve its ability to control lost circulation. However, this feature can also cause the additive to separate to the top of thin slurries and slurries containing

The environmental granular asphalt which sizes are of 0.1/40MM This recycled granular asphalt is mostly used for new roads layers and finished lines our products are backed by the European union certificates with an SGS report on each shipment.

Asphalt granular Primary use:

This type of granulate is used for stabilizing roads (second layers) and also for the first layer, mixed with cement (2%). Bitumen emulsion (2%) or any other binding.

As a result, the roads can be constructed at less cost and these roads are less harmful to the environment and much more durable.

Product details asphalt granular

We sell asphalt granular 0.1/40 also known as bitumen asphalt. Our products

Chemical composition (

It also soluble without heating in Aliphatic and low aromatic solvents (VM&P and other Naphtha,

Water-based Gilsonite is natural bitumen environmentally safe and specially formulated to protect hole shale water base drilling.

The drilling fluid serves a number of functions including taking heat away from the drill bit and facilitating the return of drill cuttings to the surface. There are three main types of drilling mud, including Gilsonite muds.

The present invention deals with the consequences of using water-based drilling Gilsonite muds. When the hydrostatic pressure of the drilling mud in the

In many applications, the drilling Gilsonite mud is intended to be deposited in and/or on the

.jpg)

PP Jumbo Bags are an excellent choice for bulk storage and transportation needs. These bags are durable, spacious, and designed to handle heavy loads efficiently. Whether for industrial, agricultural, or commercial use, Jumbo bag plastic manufacturers in India provide a reliable and cost-effective packaging solution. Their strong polypropylene material ensures protection against moisture and damage. With their high weight-bearing capacity and reusable nature, PP Jumbo Bags are a sustainable and practical option for businesses looking to optimize their logistics and storage.

ReplyDeleteThe Warning Tape Price Dubai varies greatly depending on the type, size, and customization. I was surprised to see the wide range of quality levels available. In my experience, it's better to invest slightly more in high-visibility, weather-resistant options, especially for outdoor use. Some local suppliers offer discounts on bulk purchases, which helps if you're managing a big project. Transparency in pricing is important—some vendors include printing costs while others don’t. Has anyone done a cost comparison between local and imported tapes?

ReplyDeleteYour coverage on HDPE plastic sheet is spot-on. I had no idea how many industries use it—from food processing to chemical tanks. I first encountered HDPE while working on a drainage project and was impressed by its resistance to corrosion and chemicals. It also doesn’t crack under pressure like some other materials. The environmental benefits are also a plus, especially the recyclability. I think more people should consider this for sustainable construction. Thanks for the informative write-up!

ReplyDelete